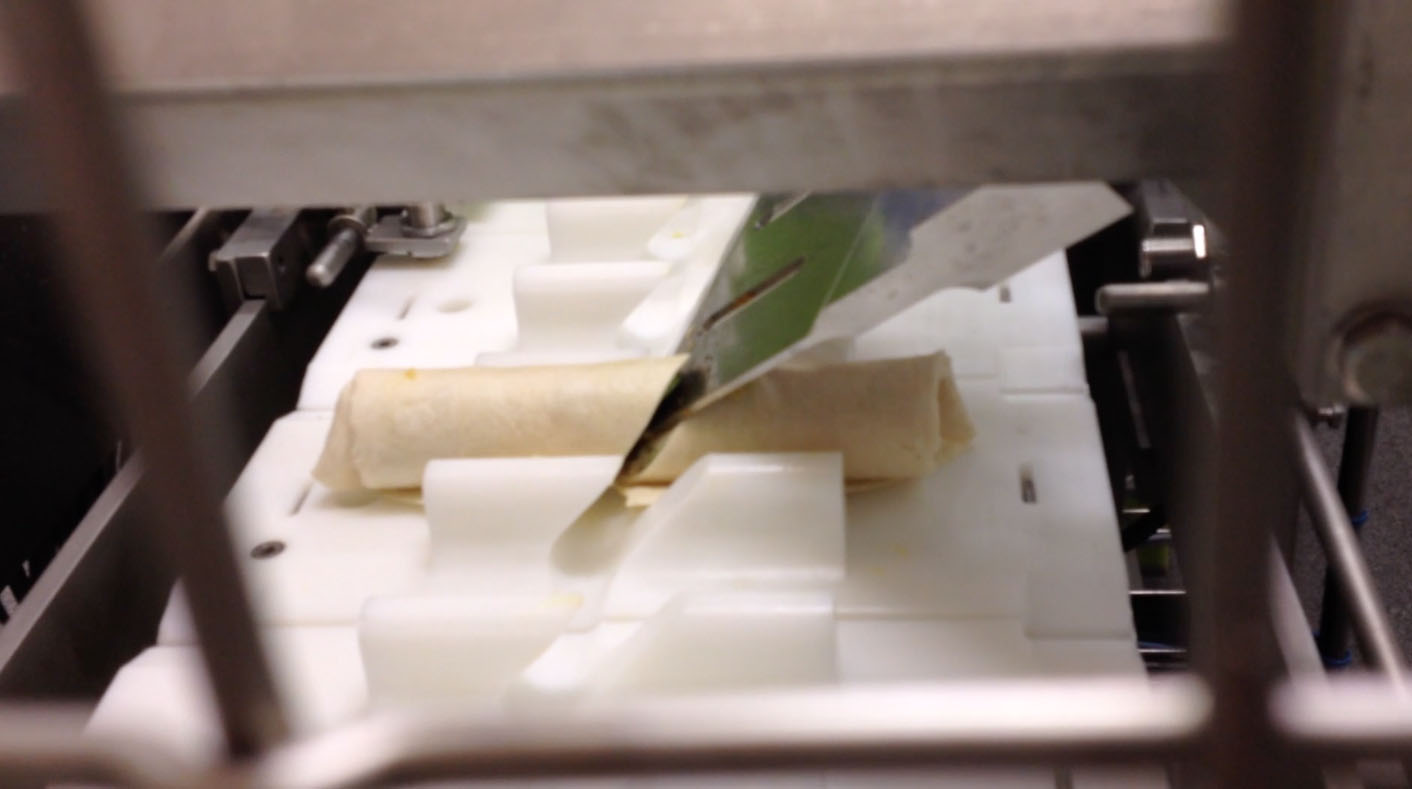

Steven BV’s fully automatic wrap line is the best solution for filling, rolling, cutting and packaging wraps in an efficient, quick and reliable manner, making it perfect for short term, fresh consumption.

Wrapmachine

Built up to the highest safety and hygiene standards, the wrap line’s unique fold and roll process guarantees neat and quick wraps. After the fold and roll process, the wraps can be cut in half or smaller bite size pieces through use of our hygienic and efficient ultrasonic cutting technology.

The wrap line consists of different modular pieces. This means that it is possible to choose where in the line each process is executed. The complete line can therefore also be customized to your specifications. For example: extra dosing units or dispensers can be added to the process or modules can be left out to make room for manual processing.

Not only can these modules be incorporated into the wrap line systems, the modules can also be sold as stand alone solutions. Steven BV provides the following stand alone solutions:

- Fold and roll units

- Cutting-units

- Inlay-units (in flowpack)

- Weighing systems (with automatic emission)

- Metal detection systems (with automatic emission)

- Transport-units

Technical specifications

Applications: Wraps

Amount of tracks: 1 or 2

Capacity: approx. 1.200 wraps per hour