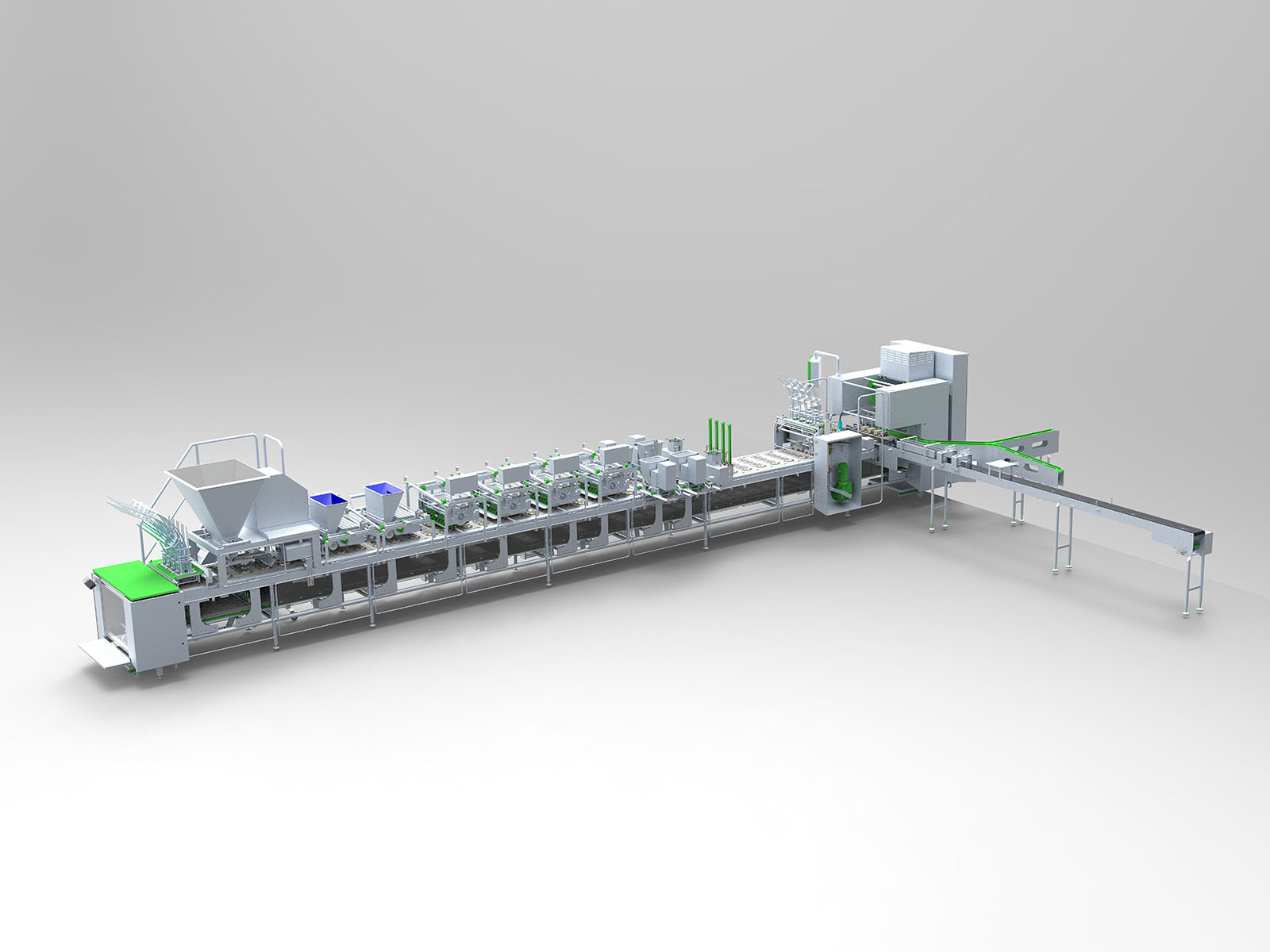

Steven BV’s line system is a fully or partially automated solution that can be used to fill, decorate and/or package a large variety of products. All of this is done in an efficient and reliable manner and up to the highest safety and hygiene standards.

Line system

The line system provides the possibility to prepare singular products (like: salads, sauces, vegetables) and combined products (like: filled salads, filled soups and pizza’s), before consumption, in high volumes.

Every line system consists of different modules. This means that it is possible to choose where in the line each process is executed and the complete line can therefore also be customized to your specifications. For example: extra dosing units or dispensers can be added to the process or modules can be left out to make room for manual processing.

Not only can these modules be incorporated into the complete line systems, the modules can also be sold as stand alone solutions.

Steven BV provides the following stand alone solutions:

- Denesters

- Dosing units

- Cutting-units

- Transport-units

- Inlay-units (in flowpack)

- Weighing systems (with automatic emission)

- Metal detection systems (with automatic emission)

Technical specifications

Applications: Salads, sandwiches, baguettes, wraps, prepared foods, sushi’s, vegetables and more

Packaging: Practically all packages

Capacity: approx. 19.000 cups per hour (dependent on product)